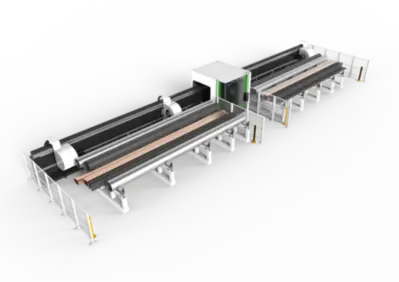

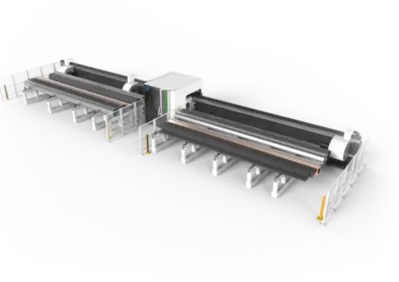

1.Segmented Splicing Cast Iron Bed

Stable

Segmented splicing cast iron bed has excellent processing property.

Durable

The usage of flake graphite with the lowest tensile strength of 200MPa gives the whole equipment strong shock absorption, wear resistance, high hardness, high carbon content, high compressive strength.

Low notch sensitivity and thermal sensitivity of cast iron bed reduces the loss of equipment in using, keeps the precision of cutting unchanged permanently and no deformation in its life cycle.

2. Four-chuck configuration

Equipped with four chucks, that makes no remaining material left under rational logic movement.

Intelligent CNC chuck self-centering precisely controls clamping position.

CNC electric chuck with a maximum load-bearing capacity of 1,800kg can clamp the tube with the maximum length of 12 meters, and the maximum clamping size range of 60mm ~ 450mm.

3.3D Cutting

Three- dimensional four-axis cutting head realizes bevel cutting in ±45° and 3D cutting.

4.Intelligent Processing

Intelligent control system can automatically choose cutting technology and realize the calibration, edge-tracing, manufacturing by the data of tube material and wall thickness.

5.Fully Automatic Loading and Unloading Device

Fully automatic loading and unloading device reduces inefficiency caused by frequent loading process, less cost and more efficient.

6.Safety and Environmental-friendly

All-round protection of cutting area, versatile air extraction and dust removal capability and various of safety sensor modules, all of which ensure the safety of personnel and equipment.

7.Floating Tube Support, Horizontal Tube Clamping

Prevent the tube from shaking and swaying in cutting process.

8.Wide-Range of Tube Cutting and Wall Thickness

The wall thickness of tube is of 3mm to 20mm, and all sorts of tube include round tube,square tube,rectangular tube,polygon tube, long round tube, oval tube, angle steel, joist steel, channel steel, H-beam, etc.

Available Options:

Reaming&Tapping: Multi-station, automatic tool selection, up to M12 tapping.

Weld identification: Recognize the weld location and automatically avoid weld to ensure the quality of cutting surface.

We use cookies to improve your experience. Privacy Policy.