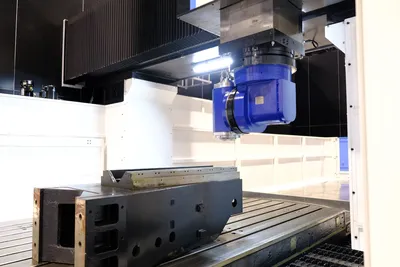

2025 NEWAY PM-2030HC Double Column 5-Face Bridge Machining Center – Precision and Versatility for Complex Part Manufacturing

The 2025 NEWAY PM-2030HC Double Column 5-Face Bridge Machining Center is a high-performance CNC machining solution designed to deliver exceptional precision, stability, and versatility for a wide range of demanding applications. Built with a robust double column design and equipped with a 5-face machining capability, this machine is ideal for industries such as aerospace, automotive, energy, and general manufacturing. It is engineered to handle large, complex parts, delivering superior results in both high-precision and high-volume production environments.

Key Features:

Double Column Design: Provides superior rigidity and stability, minimizing vibrations and maximizing accuracy during heavy-duty machining, especially for large and complex parts.

5-Face Machining Capability: Offers the ability to machine five sides of a part in a single setup, reducing cycle times, improving part accuracy, and increasing overall productivity.

High-Speed CNC Spindle: Achieves rapid material removal and fine surface finishes across various materials, including steel, aluminum, and titanium, ensuring precision and efficiency.

Precision Linear Guideways: Ensures smooth, accurate movement, improving part repeatability and maintaining high performance over long production runs.

Advanced CNC Control: Features an intuitive control system, supporting complex programming and simplifying setup for operators of all skill levels, increasing operational efficiency.

Large Work Envelope: Accommodates large workpieces, expanding the machining center’s versatility to handle a wide range of part sizes and geometries.

Automatic Tool Changer (ATC): Boosts efficiency by allowing for fast, reliable tool changes, minimizing downtime and optimizing production cycles in high-mix manufacturing environments.

Efficient Chip and Coolant Management: Provides effective chip removal and coolant management, maintaining a clean work environment and ensuring optimal machining performance during extended operations.

The 2025 NEWAY PM-2030HC Double Column 5-Face Bridge Machining Center is the ideal solution for manufacturers seeking a high-precision, versatile, and heavy-duty CNC machining center. Its robust design, advanced features, and ability to perform 5-face machining make it perfect for complex, large-scale part production, ensuring consistent, high-quality results in both low and high-volume manufacturing environments.

CAPACITY:

Table Size: 118" × 79" (3,000 × 2,000 mm)

Spindle Nose to Table: 9.8" – 49.2" (250 – 1,250 mm)

Max. Part Height: 49" (1,250 mm)

Max. Table Load: 30,900 lbs. (14,000 kg)

Distance between Columns: 110" (2,800 mm)

TRAVEL:

X Travel: 126" (3,200 mm)

Y Travel: 106" (2,700 mm)

Z Travel:40" (1,000 mm) without 90° head

33" (840 mm) with 90° head

SPINDLE:

Max. Spindle Output: 40 HP (29.8 kW)

Spindle Speed: 40 – 4,500 RPM

Max. Torque: 672 ft-lb (910 Nm)

Spindle Taper: CT / BT 50

2-Speed Gearbox: German ZF

X-AXIS:

Rapids: 591 IPM (15 m/min)

Cutting Feed Rate: 394 IPM (10 m/min)

Slide Way: Two heavy-duty roller guideways

Y-AXIS:

Rapids: 787 IPM (20 m/min)

Cutting Feed Rate: 394 IPM (10 m/min)

Slide Way: Two heavy-duty roller guideways

Z-AXIS:

Rapids: 591 IPM (15 m/min)

Cutting Feed Rate: 394 IPM (10 m/min)

Slide Way: 400 × 400 mm RAM with box ways

AUTOMATIC TOOL CHANGER:

Tool Stations: 40 tools

Max. Tool Diameter: 4.13" (105 mm)

Max. Tool Length: 13.8" (350 mm)

Max. Tool Weight: 33 lbs. (15 kg)

Pull Stud Type: MAS 403 P50T-1

Tool Change Type: Horizontal and vertical directions

GENERAL:

Coolant Tank Capacity: 265 gallons (1,000 L)

Power Supply: 220V, 3 phases

Power Consumption: 60 KVA

Air System Pressure: 6 – 8 bar (87 – 116 psi) at 500 L/min (17.7 CFM)

Machine Gross Weight: 79,400 lbs. (36,000 kg)

Floor Space (L × W × H): 30' × 22' × 20' (9,020 × 6,500 × 5,400 mm)

2-speed German ZF spindle gearbox

3-color cycle light

Air gun

Air conditioner electric cabinet

Automatic lubrication system

Absolute encoder feedback system

Chip conveyor

Coolant system w/ 1000 Liters coolant tank

Easy Maneuverable Overhead Control Pendent

Foundation kit with leveling screws and pads

Fullsplash guards

Hydraulic system

Internal chip augers

LED work light

Nitrogen control hydraulic counter-weight balance system

Oil skimmer

Operation manual

Operator platform

Pneumatic system

Remote MPG

Safety catwalk for maintenance at top of cross rail

Spindle Air Purge

Spindle oil chiller

Scrap cart

Toolbox with hand tools

Water gun

Way covers on all axes

Way lubrication oil collector

We use cookies to improve your experience. Privacy Policy.