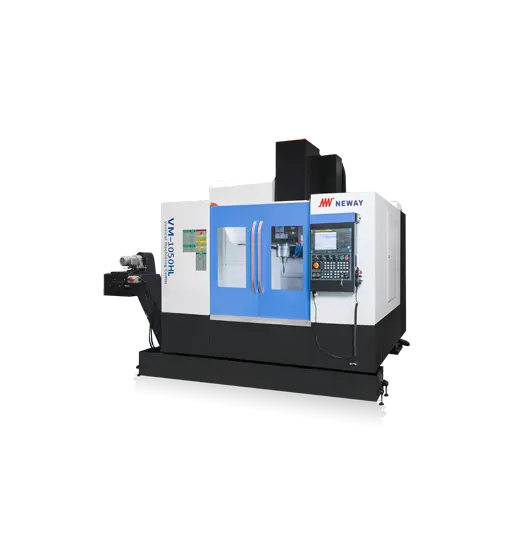

The VM1050SL/HL Vertical Machining Center is engineered for high-speed, high-precision CNC machining, making it an ideal solution for industries such as aerospace component manufacturing, automotive die machining, precision mold making, and heavy industrial fabrication. Designed for rigid milling, drilling, tapping, and contour machining, this machine offers exceptional cutting performance, efficiency, and durability for steel, aluminum, titanium, and composite materials.

With a powerful 7.5/11 kW (10/14.8 HP) direct-drive spindle motor, a BT40 spindle taper, and a 24-tool automatic tool changer (ATC), the VM1050SL/HL is optimized for fast setup times and uninterrupted machining cycles. The oil-cooled spindle ensures thermal stability, while rapid X/Y/Z axis travel speeds of 1,890 inches per minute allow for efficient material removal rates and reduced cycle times.

Key Features for Industrial Manufacturing:

✅ 12,000 RPM (15,000 RPM optional) high-speed spindle for superior surface finishes

✅ Worktable size of 39.3" × 20.5" (1000 × 520 mm) for increased machining flexibility

✅ FANUC CNC control system with high-speed processing for precision machining

✅ Positioning accuracy of ±0.0003" and repeatability of ±0.0002" for tight-tolerance parts

✅ Ideal for high-volume CNC machining, mold and die applications, and precision component production

The VM1050SL/HL is the perfect machining solution for CNC job shops, contract manufacturers, and OEMs looking to increase productivity and machining accuracy while reducing operational costs. Contact us today to learn how this machine can streamline your production and maximize profitability.

VM1050SL/HL

Worktable Size: 39.4 × 20.5 in

Max. Worktable Load: 1210 lbs

Axis Travel (X/Y/Z): 33.5 / 20.5 / 22 in

Spindle Terminal to Worktable: 4.7 - 26.8 in

Spindle Center to Column Guideway: 22.8 in

Axis Rapid Travel Speed (X/Y/Z): 1890 / 1890 / 1890 in/min

Spindle Motor Power: 10 / 15 hp

Max. Spindle Speed: 12,000 [15,000] rpm

Spindle Taper: 7:24 taper NO.40

Spindle Temperature Control: Oil cooler

Number of Tools (Disc Type): 24

Tool Shank: MAS403 BT40

Max. Tool Diameter / Length / Weight: Ø3.15 in / 11.8 in / 17.6 lbs

Tool Change Time (T-T): 1.8 sec

Drilling Capacity (Normalized Carbon Steel): Ø1.57 in

Tapping Capacity (Normalized Carbon Steel): M20

Milling Capacity (Normalized Carbon Steel): 12.2 in³/min

Positioning Accuracy (X/Y/Z): 0.0003 in

Repeatability Accuracy (X/Y/Z): 0.0002 in

CNC System: NEWAY FANUC [SIEMENS/Mitsubishi]

Auto Chip Conveyor: Side way

Machine Weight: 12,350 lbs

We use cookies to improve your experience. Privacy Policy.